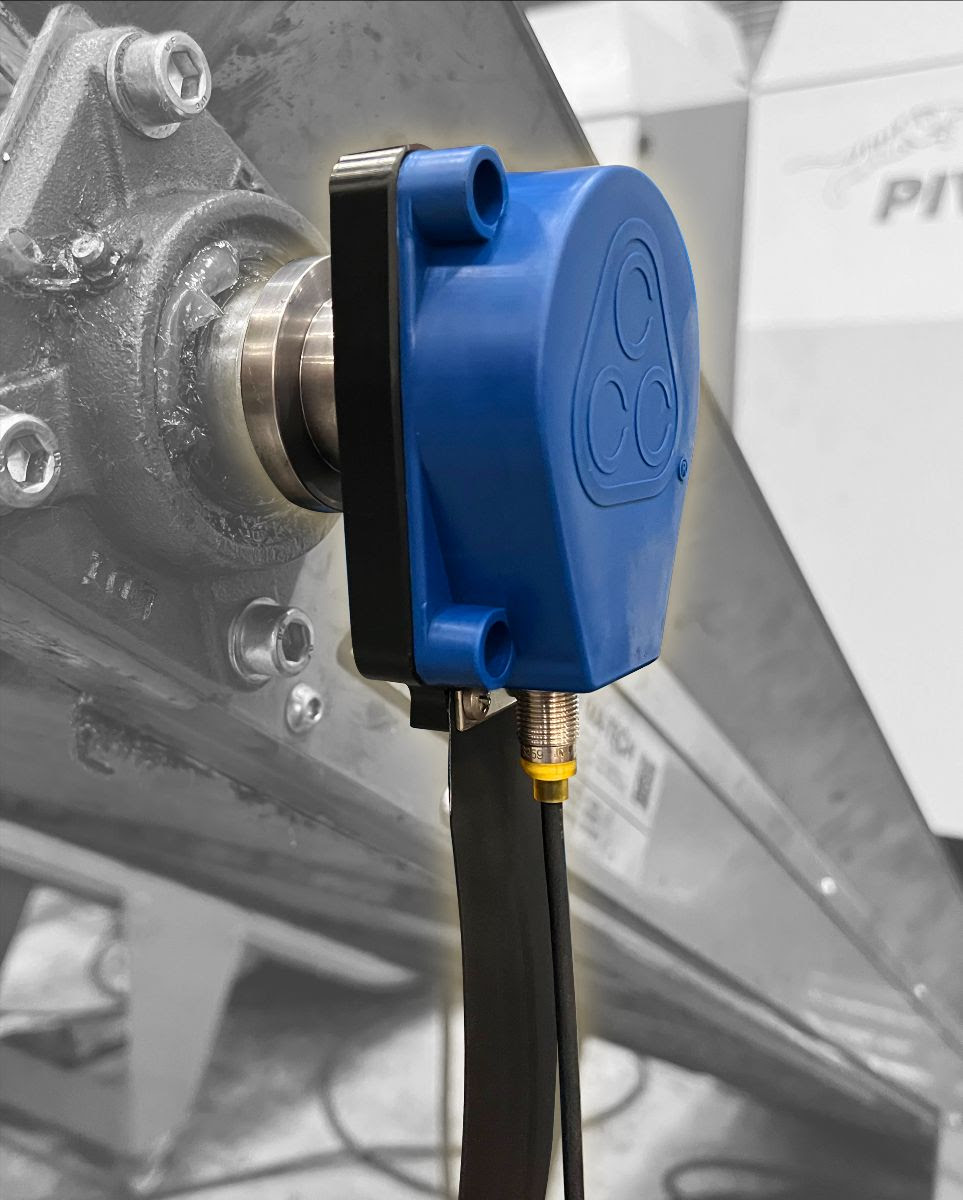

Simply attach and go, Conveyor Components Company said of its newest product addition, the Mag-Neat-O magnetically coupled and self-contained motion speed control.

The product magnetically couples to the end shaft of the tail pulley and indicates when a conveyor belt has slowed or quit moving altogether. The pulse output of the Mag-Neat-O can be wired into a PLC or DCS, which can easily determine under speed, overspeed or zero speed of the conveyor.

Optionally, the Mag-Neat-O can be connected to the model RMS-G (using the two-wire sensor) or MSD-800 controller (using the three-wire sensor), which supplies relay outputs to control up to two separate circuits, one for machinery shutdown and one for an alarm.

“The Mag-Neat-O can shut down rotating equipment before severe damage is encountered,” CCC said. “It provides protection for interlocked conveyor belts, especially if one of the belts fails due to overloading or quits due to conveyor belt tearing/separation. The standard construction is a chemical and impact resistant polymer material, with stainless steel internal parts.”

The company said another advantage to the new release is that no drilling or tapping of the tail pulley shaft is required, as the unit is held in place with a strong magnetic connector on any non-driven pulley shaft. The compact design will fit in most places on a conveyor system.

Source: Conveyor Components Company