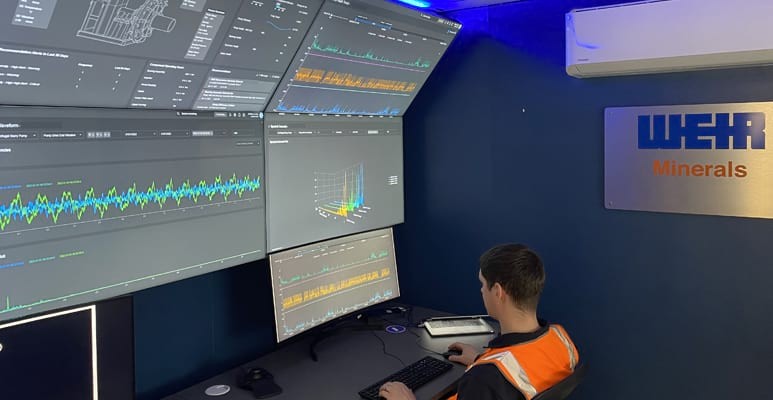

Weir Miners has partnered with digital twin platform XMPro, pairing it to enhance its Synertrex digital ecosystem for real-time insights and decision making.

The partnership, it said, will enable intelligent equipment and services for its customers, and also support miners in their missions for higher performance and reducing their operational environmental footprints.

The XMPro platform can identify critical events by applying artificial intelligence and predictive analysis for next-generation predictive services.

“It allows for data orchestration and value creation from multiple sources, including sensors, miners’ digital ecosystems, and data only available to Weir Minerals as an OEM, like maintenance data and 3D engineering models,” Weir noted.

The use of XMPro will offer reliability in a user’s insight, which can be viewed via mobile devices and the Synertrex intelligence web portal.

This new partnership follows Weir’s announcement earlier this month that it had signed a digital partnership framework for strategic cooperation with end-to-end software supplier AVEVA.

Weir will utilise the AVEVA PI system to collect and contextualize IIoT data streams, which will become the IIoT data foundation of its Synertrex digital ecosystem, the company noted.

Director Digital Ole Knudsen pointed out that, for the foreseeable future, these platforms – and the building of multiple data-source digital twins – will offer greater value for customers and “close the loop” between real-time operations, equipment design and manufacturing.

‘XMPro takes an actionable and collaborative approach to data that closely aligns with our Synertrex digital ecosystem; it is a platform ensuring maximum customer value from all the data we collect, ranging from equipment and process data to the in-house data we have access to as an OEM,” Knudsen noted.

“We see the multiple data source approach as essential to build the holistic digital twins providing ‘intelligence’ to our customers in terms of insights, predictiveness, and recommendations allowing for a proactive approach to maintenance planning and execution.”

Source: global.weir