Flexco has acquired SHG Conveyor Control GmbH, the creator of Rip Prevent+, an advanced AI-powered conveyor monitoring system that enhances conveyor efficiency. Rip Prevent+ delivers real-time belt rip detection, prevention, and operational insights – without sensors inside the belt, lasers, cameras, or structural modifications. This plug-and-play solution works with any conveyor, enabling rapid deployment and immediate value for operators in…

Read MoreTag: Flexco

Flexco debuts Flextreme PXT cushion

Flexco recently announced the addition of the Flextreme PXT Secondary Belt Cleaner Cushion to its line of belt conveyor products. Specifically designed for extreme heavy-duty mining applications, the manufacturer noted, the PXT helps convey larger material tonnages at higher speeds, all while keeping belt conveyor systems clean. Full story.

Read MoreFlexco lifts the bar with BSB

Flexco has added the Belt Support Bar (BSB) to its line of heavy-duty belt support system tools. Featuring the company’s standard purple paint, the new release can immediately create a better seal once installed onto a facility’s conveyor belt and can mitigate the release of dust while creating a more efficient, safer belt conveying process. Flexco Product Manager Kevin Fales…

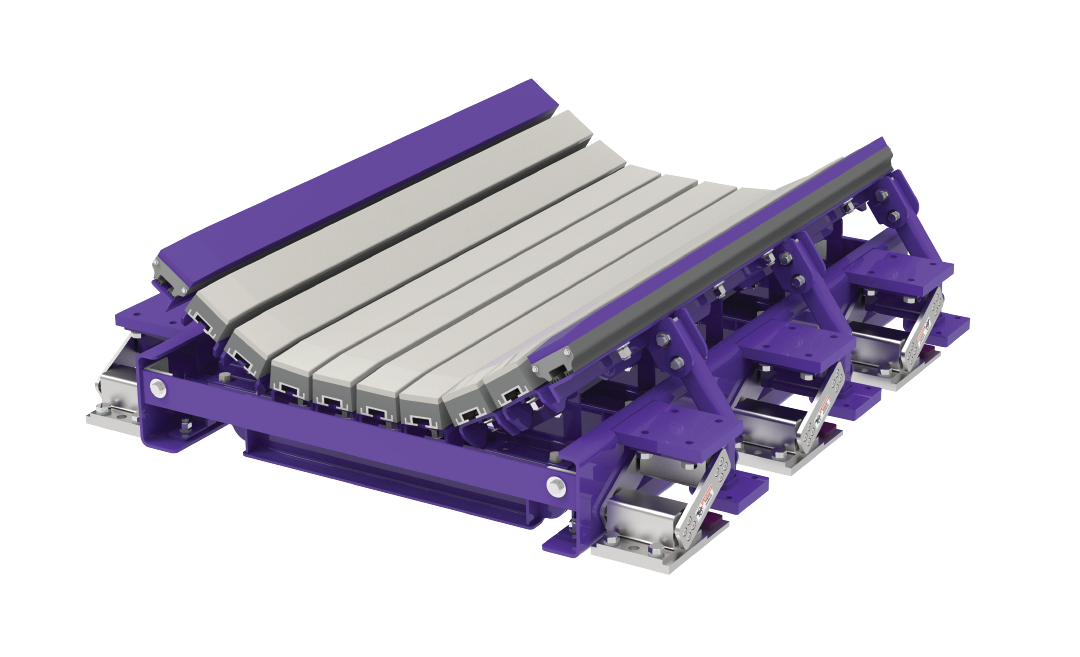

Read MoreFlexco introduces new impact bed

Flexco recently added the DRX 4500 to its line of impact beds and skirting systems. By utilizing Velocity Reduction Technology, this new model gives heavy-duty belt conveyor systems the ability to withstand impact energy from 1500 to 4500 lb.-ft. (200 to 600 kg/m). “The DRX 4500 is set to make a major impact on our partners in the heavy-duty mining…

Read More