The U.S. Mine Safety and Health Administration requested in late December that any mines using Ocenco M20.3 SCSRs visually inspect every unit due to a known issue. This is in addition to its outline that the units must be worn in the approved black case and visually inspected at the beginning of each work shift.

During mandated approval audits, the National Institute for Occupational Safety and Health (NIOSH) evaluated 16 belt-worn M20.3 Ocenco units that had been in service at an active coal mine. The testing revealed that three of the 16 units were found to contain white sorbent dust inside the breathing bag. Miners coming into contact with sorbent material may experience respiratory distress and skin irritation.

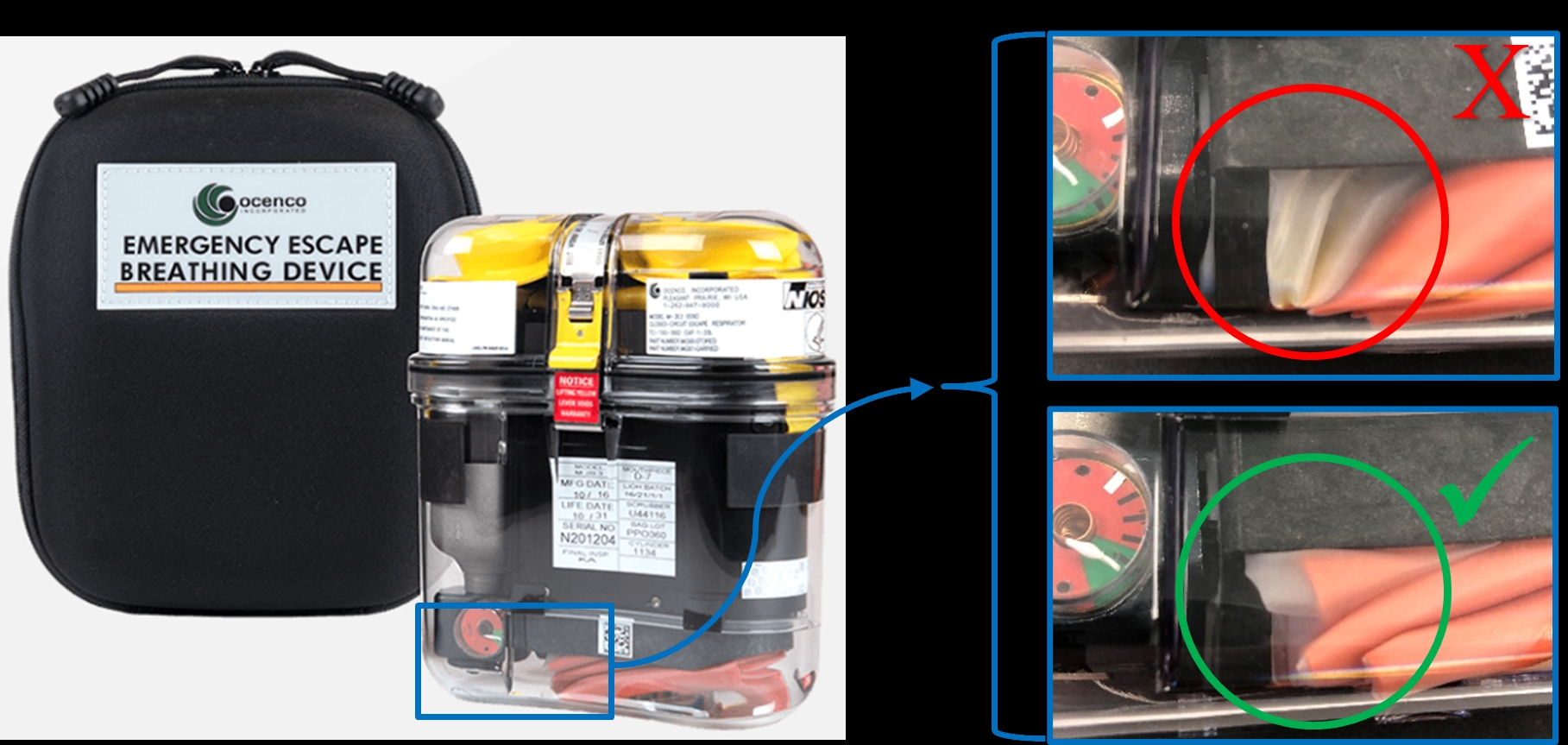

Visually inspect the M20.3 by looking through the clear base and checking for the presence of white dust within the clear breathing bag. Units with sorbent inside the breathing bag may not perform for their rated duration and must be removed from service immediately.

Ocenco M-20.3 units must be worn in the approved black case and visually inspected at the beginning of each work shift. If stored, units must be visually inspected every 90 days. More information can be found in the product manual.

The OEM also has more information on the unit available at www.ocenco.com/media/1024/m-203-instruction-manual-ocenco-inc.pdf.

MSHA said its best practices include:

- Inspection overview from manufacturer’s manual.

- Verify the presence of tamper indicating ball on the latch lever.

- Verify that the pressure gauge is reading in the green zone.

- Visually inspect the unit for damage.

- Sorbent dust in breathing bag visible through case.

- Case cracked, burned, deformed or excessively worn.

- Excessive gap between the cover and base.

- Damaged latch or cover band.

- Dirt or debris visible through case.

- Moisture visible through case.

- Verify the unit is within life cycle dates.

- If the unit fails any part of the inspection, remove the unit from service.

Source: MSHA