Discover how backstopping clutches play a critical role in your operation’s safety.

Backstopping clutches, also called holdbacks or backstops, are a safety measure to prevent reverse movement of incline conveyors, bucket elevators or pump systems. Their crucial role helps protect critical equipment from damage and support worker safety.

How Do Backstops Work?

In backstop applications, backstops allow the drive shaft to rotate freely in one direction. As soon as torque is reversed, however, the clutch automatically locks into place to prevent any movement in the opposite direction. This ensures that machinery, like a conveyor belt carrying heavy bulk materials, does not roll backward.

However, not all backstops offer the same safety and reliability. Even if a backstop has been selected appropriately for an application, unanticipated high-torque loads can cause it to fail, resulting in a rollover. Costly damage, personal injury, and/or downtime may occur if a backstop does not fulfill its function.

For high-torque applications, reliability is key. New innovations in backstop technology make it possible to prevent rollover and ensure maximum protection for equipment and employees.

Thermal Application for Proactive Maintenance

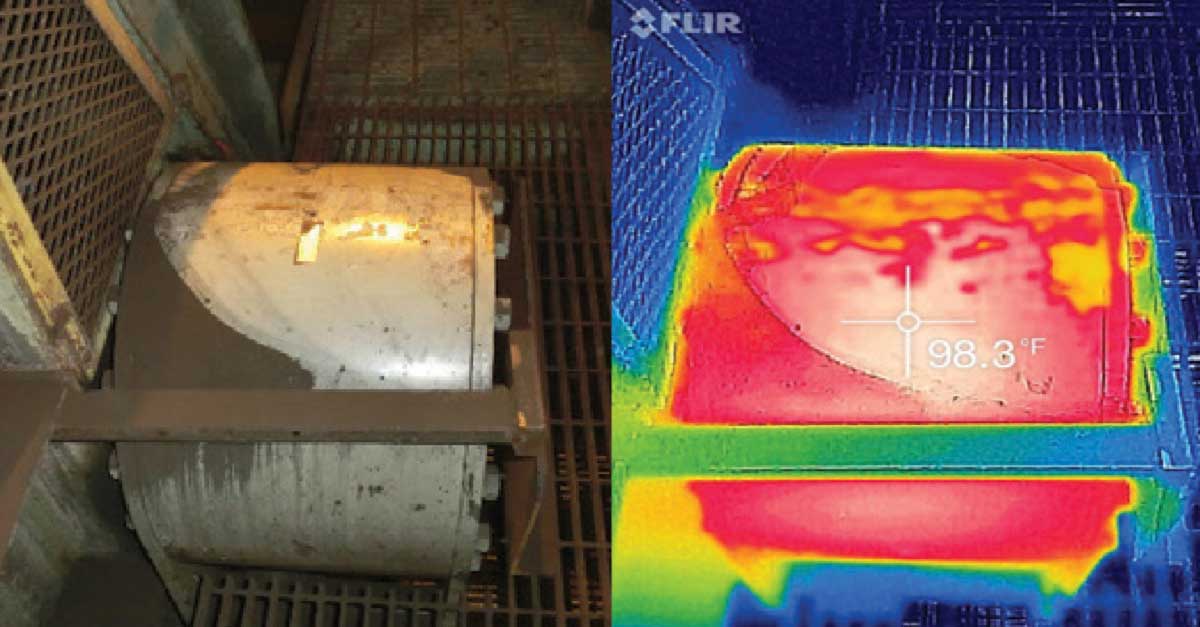

Preventative maintenance and performance monitoring are also critical. Temperature rising in backstops utilizing oil can be a sign that the backstop needs maintenance or replacement. U.S. Tsubaki has developed a thermal app that allows for real-time monitoring of temperature and can create formal reports on the status of backstops being utilized on multiple pieces of equipment. This helps operators prevent costly breakdowns and ensure uninterrupted operation. Proactive identification and maintenance will reduce downtime and enhance overall operation safety.

Non-Rollover Backstops

Advanced engineering of the shape and size of the cam element can help enhance backstopping ability. Tsubaki’s BS-F series backstop uses a custom engineered cam design that has a larger profile and higher torque rating than other leading competitors. Even if an unexpectedly large reverse torque occurs, the cams will not roll over, preventing a conveyor from reversing.

The BS-F offers several other enhancements to extend wear life and improve performance. To reduce friction between components, the BS-F utilizes synthetic grease lubrication in a labyrinth-sealed design. This lowers the amount of required maintenance, by removing the need to monitor oil levels, refill the backstop, or measure the amount of moisture in the lubricant. The grease in a BS-F only requires yearly changing for most applications. The labyrinth seal design also prevents dust and other contaminants from getting into the clutch assembly, minimizing wear and ensuring a lower operating temperature. U.S. Tsubaki offers a wide variety of backstop products that can significantly help optimize your operation from a productivity, profitability and safety standpoint.

On-Plant Survey and Thermal Imaging

U.S. Tsubaki also offers a Thermal Imaging application that can generate a formal report of your entire facility. The program includes an on-plant survey of all equipment utilizing backstops and clutches, formal training for personnel and demonstration of the Tsubaki Thermal Imaging App, all at no additional cost. Sign up for your own survey or learn more about the Thermal Imaging application by clicking here.

Need more information about our U.S. Tsubaki backstops? Reach out to a sales representative to find the solution for your operation’s unique needs or visit our website at ustsubaki.com.