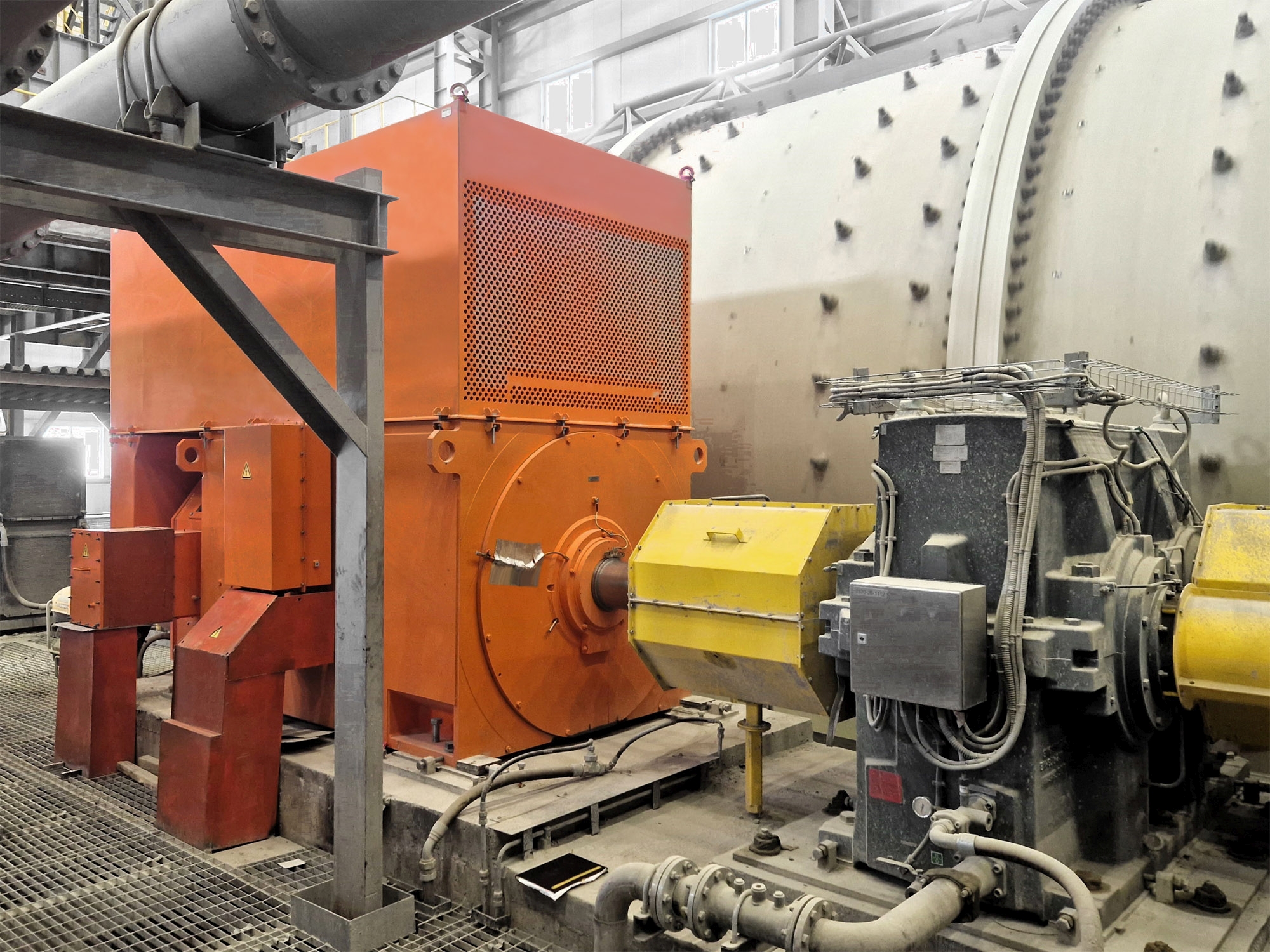

Menzel Elektromotoren has configured two modular slip ring motors from its extensive stock for a ball mill in a gold mine in Kazakhstan – and were able to ship them at short notice.

The company said its motor pair will provide the necessary high starting torques for the heavy-duty application and ensure reliable operation under impact loads and voltage fluctuations.

The MEBSSL motor series allows for swift individual modifications and the implementation of different features, such as various cooling and protection classes or mounting options. The series is characterized by high efficiencies, minimal operating costs, great robustness and a long service life.

The two identical mill motors in size 800 are designed in the increased protection class IP55 and in cooling class IC 611 with an air-to-air heat exchanger. The nominal power is 4750 kW, the nominal voltage is 10000 V, the nominal torque is 45682 Nm, with permissible maximum torques of 290%.

Menzel both manufactured and fitted new shaft ends, and also added new foot holes. It also shortened and moved the rotor terminal boxes and added additional auxiliary terminal boxes for the slip ring chamber.

“The motors reached the customer within a very short time, thus preventing extended, costly mill downtime,” Menzel said. “[We] accompanied and supported the installation and commissioning. The German family-run company supplies the mining industry with suitable motors for a wide range of applications.”