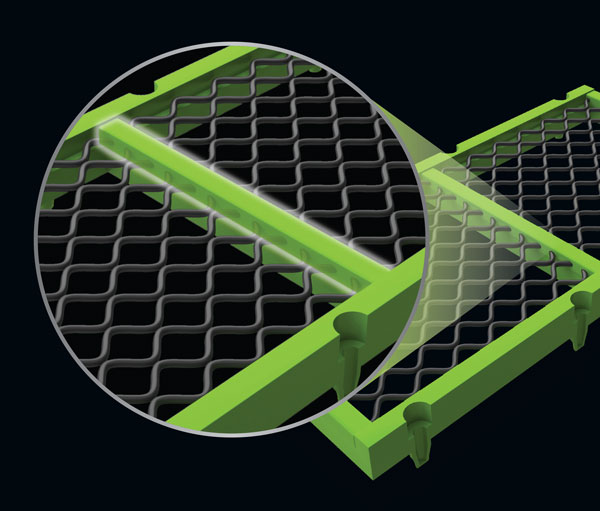

Canadian-based screen media supplier MAJOR has introduced an advanced polyurethane (PU) strip variant for its Flex-Mat Modular series that increases the screen media’s durability and extends its lifespan and effectiveness in wet and corrosive environments.

The advanced PU strip features greater chemical stability to improve performance in alkaline, acidic and wet environments, such as limestone operations. Advanced durability extends the overall wear life of screen media in applications where the PU strips typically wear out before the steel wire and affect the integrity of the screen media.

“While most screen media provide excellent durability, we noticed accelerated wear in some corrosive applications,” said R&D manager Kevin Laporte. “We immediately began testing to create a corrosive-resistant alternative we could develop into a new polyurethane variant. The new polyurethane strips would allow these specialty operations to benefit from FLEX-MAT’s productivity-boosting qualities while still maximizing uptime.”

OPTIMUMWIRE bonds to the company’s distinctive lime green PU strips to offer higher wire vibration than woven wire screen media, and the chemical compound developed for its advanced PU strips holds up well against corrosive materials to ensure the strips match the lifespan of its OPTIMUMWIRE products and maintains screening integrity longer, up to 10 times in some cases.

“The new durability of the PU strips still allows the same flexibility as our standard option so the wires can vibrate freely. The high frequency of the OPTIMUMWIRE wire remains – 8,000 to 10,000 cycles per minute – to speed up material separation and passing,” Laporte said.

Like MAJOR’s standard polyurethane composition, the advanced PU strips are available for the FLEX-MAT Modular D, S and T Series. The new variant is not intended to completely replace the standard polyurethane.

“Instead, they’re a special-order option for screen media going into harsh environments,” Laporte said. “The best use of the advanced PU strips is when operations are screening corrosive or wet materials or when the operation notices their polyurethane is breaking down faster than the steel wire. In most cases, the standard polyurethane strip option continues to perform optimally for our customers.”

All Flex-Mat screen media feature the company’s signature Flex-Mat ID Enabled technology with an RFID tag embedded in the frame. This technology allows customers to easily access product information by scanning the RFID chip with the MAJOR app. Customers then have access to all screen media specifications and the ability to reorder without the need to climb onto the screen for physical measurements.

Source: MAJOR