Aurubis AG, which announced in August 2023 its decision to invest in hydrogen-ready anode furnaces at its Hamburg copper processing plant in Germany, has brought in Metso to assist in the goal.

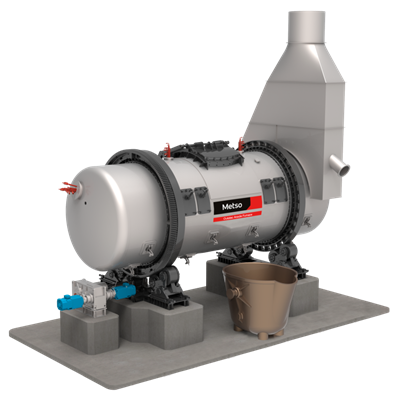

Metso’s proven technology, the company said, has consisted of complete hydrogen-ready Outotec Anode Furnaces with hoods and auxiliary equipment, which will be used in the anode refining process. Close collaboration with Aurubis was key in designing the hydrogen-ready furnace by Metso, a first in the copper industry.

Design input was based on full-scale hydrogen testing done at the Aurubis plant in 2021. The order, the value of which is not disclosed, was booked in Metals’ first-half 2023 orders received.

Aurubis expects the new technology in copper production to provide potential savings of 5,000 tonnes of CO2 per year. The Hamburg plant will be one of the first copper smelters in the world to use hydrogen instead of natural gas for the reduction process in its anode furnaces.

“Metso’s Outotec Anode Furnaces are designed for safety and sustainability, enabling lower energy consumption, decreasing batch cycle time for more efficient refining, and resulting in cleaner off-gases. Metso can provide anode furnaces powered with steam reformation or hydrogen capabilities, both of which can significantly reduce process CO2 emissions compared with traditional processing media,” the supplier said.

Source: Metso